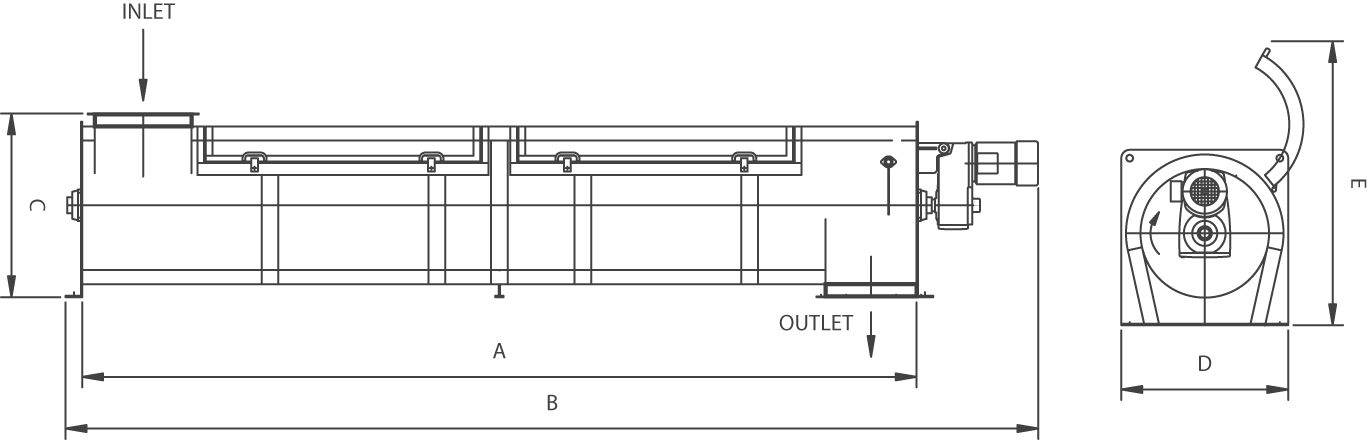

The Ottevanger Continuous Coaters are perfectly suitable for adding and mixing liquids, evenly on pellets and/or extrudates. By dosing the liquids through a spray box, the product and liquids are slowly mixed together. The trough of the coater itself is executed in stainless or mild steel, with 2 inch thick insulated jacket. The heat tracing stimulates the absorption of the liquid and avoids contamination of the trough. The coater is equipped with hinged inspection hatches over the full length of the mixing trough, which allows easy access. Apart from oil and/or fat, also vitamins, enzymes etcetera can be added in small quantities. Dosing systems for these products are available upon request.

Receive more information