- Ottevanger

- Conditioning

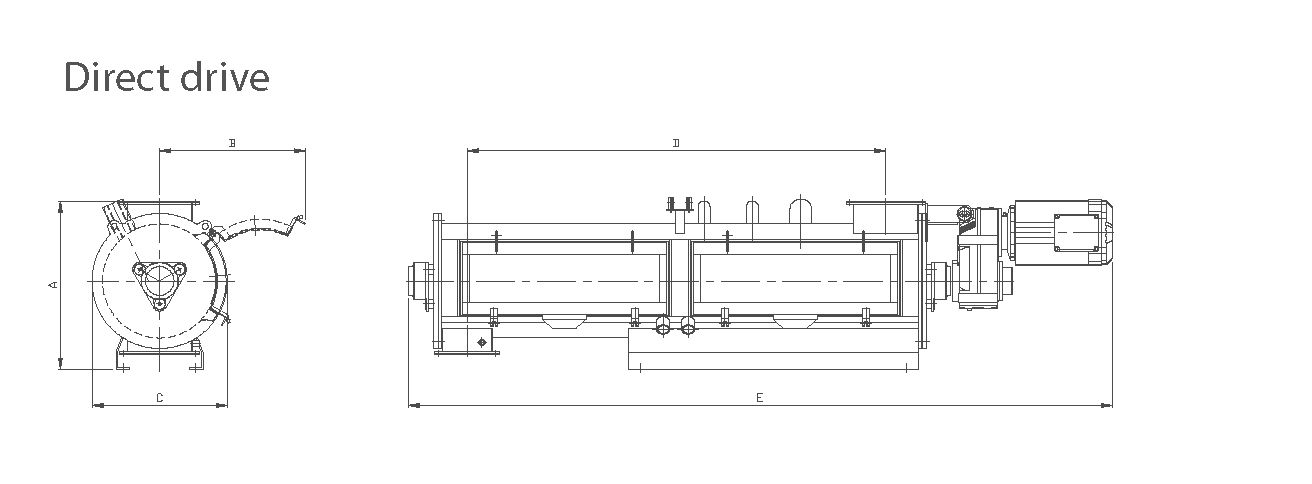

- Single Conditioners

Single Conditioners

The details in development and engineering make the difference in this conditioner. Generously sized paddles, adjustable in both height and pitch, create a homogeneous mixture and an hygienic process. The robust, low-maintenance machine can be combined with a feeder screw and steam set and contributes to an optimum absorption of steam and liquids. There is a choice of two options: a standard conditioner mixer and an insulated, electrically heated version which minimizes the formation of condensation and premature cooling. Development and engineering details make the difference in this stainless-steel conditioner. Large-scale paddles whose height and angle can be adjusted generate homogenous mixing and a hygienic process. The conditioner is often supplied in combination with a feeder screw and steam set.

Features Single Conditioners

- Mixer housing in AISI 304, base plate construction in heavy

duty steel - Solid mixer shaft in AISI 304 with interchangeable paddles,

adjustable in both height and pitch - Paddle holders in AISI 304, paddles in Hardox

- Built-in scrapers at endplates

- Stuffing box sealings on mixer shaft

- Closed shaft bearings on spacers outside the housing

- Direct drive by gear motor. Suitable for frequency control. Frequency converter not included.

- Large inspection doors with safety switch

- Temperature sensor PT 100

- 1 steam inlet 3” and 2 liquid inlets 1½”

- Electric heat tracing system, insulated with rock-wool (optional)

Advantages

- Homogeneous mixing and hygienic process

- Optimum absorption of steam and liquids

- Robust construction of the housing

- Easy to clean

- Longer maintenance intervals

- Simple design