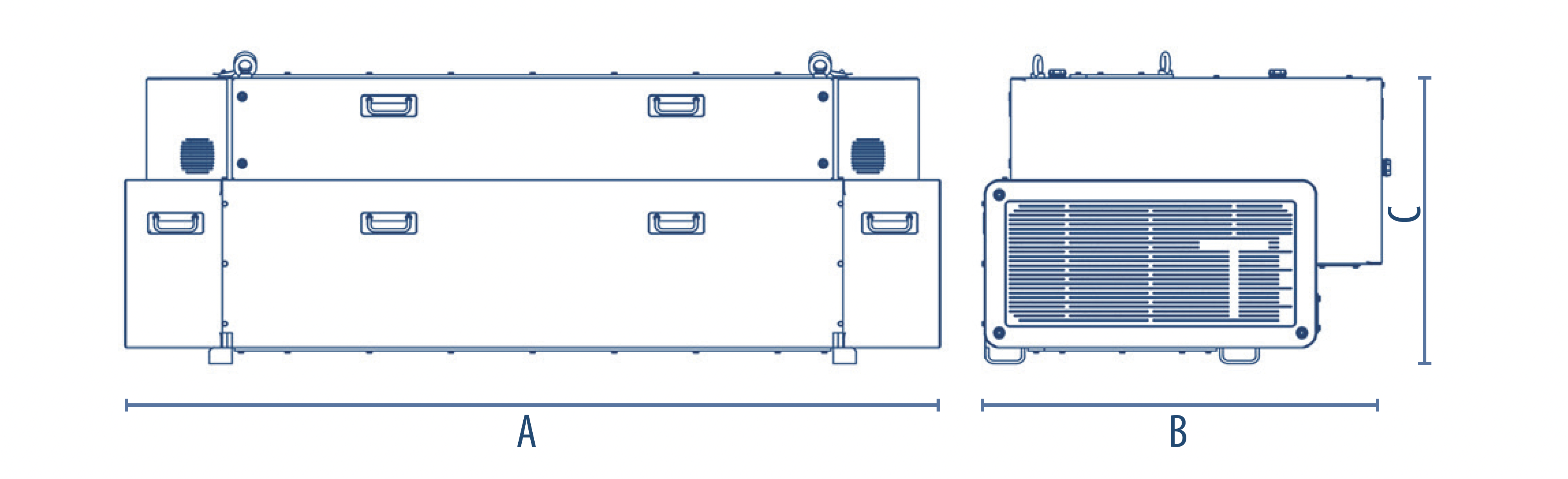

High Efficiency Line

The development of our new High Efficiency (HE) line concentrated not only on higher performances and a more hygienic design but also lower energy consumption.

The new HE line gives excellent access to all maintenance areas. With this HE line Ottevanger takes a new step forward.

High Efficiency advantages

- More capacity with same energy level

- Frequency controlled dual rotation feeder (by-pass function), frequency converter not included

- Rollers are exchangeable from front and the sides

- 50% more revision options of the rollers

- Easy access for maintenance