You are here:

- Ottevanger

- Grinding

- Roll feeders

Roll feeders

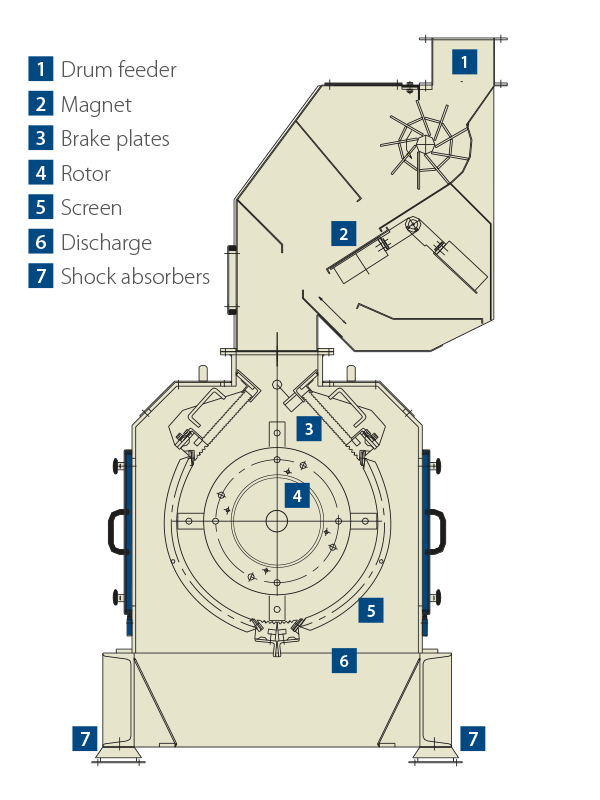

The Ottevanger Roll Feeders guarantees an even supply to the hammer mill and is driven by a special 2.0 HP motor reducer which can be regulated by a frequency converter. It has an integral stone catcher for removal of heavy particles. Iron particles are extracted by an extra-strong permanent magnet with an automatic cleaning system. The items removed are collected in a tray. The feed roller, stone catcher, magnet and collection tray are assembled into a fully sealed feed unit. The special, multiple dosing screw can be used as an option for very fatty products and products with poor flow characteristics.

General

- Capacity up to 60 mt/h depending on type of product

- Maximum feed width: 50 inches

Application area

Above all types of hammer mill and/or roller mill in the animal feed, pet food and aqua feed industry.

Options Roll Feeders

- Feed roller speed can be adjusted by means of a motor reducer and frequency control

- Iron extraction magnet

- Automatic magnet cleaning

- Adjustable air inlet valve (with automatic model)

- Stone catcher

Available on request

- Feed unit for products with low transportability or bulky products (screw feeder)

- Automatic product load monitoring